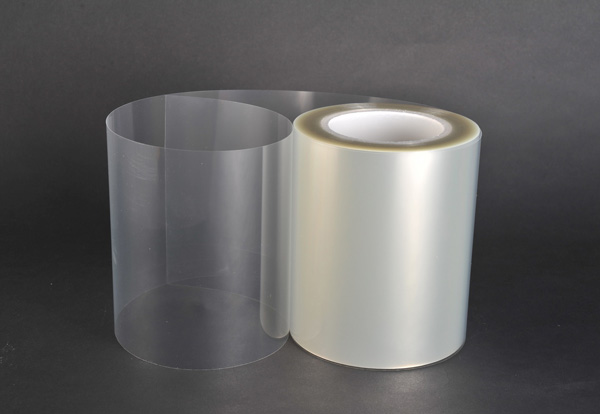

Corona treatment of 250 micron PET film

May 27, 2022|

May 27, 2022| View:267

View:267250 micron pet filmaccording to Gravure printing method, printed design, can have the role of cleaning commodity packaging, a product with excellent publicity planning role, with other printing materials can not be compared to the advantages. However, the most common plastic film materials are non-polar polymers with very low surface free energy. In theory, if a certain kind of object's surface freedom is too small, then basically can not pay at this stage known any kind of adhesive. Therefore, in order to make the printing ink on the surface of polyolefin packaging fastness, it is necessary to enhance its surface-free energy. By far the most widely used solution for 250 micron pet film in the world is corona treatment.

Because corona treatment is usually carried out in the air, under the shock criterion of high-pressure and high-frequency spark discharge, on the one hand, weak electrolyte occurs in the gas, resulting in various polar functional groups; On the other hand, the double chain in the molecular formula of polyene, especially the double chain on its carbon bond, is easier to open. Thus, in a split second of the solution, various polar functional groups are grafted onto the surface of the polymer, thus changing the polyolefin surface from non-polar to polar. Yes, that is to say, the surface of the polyolefins, which have been solved by arc discharge, is about 10-10 meters thick and has become a polar chemical which is completely different from the structure of the polyolefins, the surface free energy of 250 micron pet film is further enhanced. In addition, high-voltage high-frequency spark discharges will plastic film the surface of the material according to impact, which in turn increases the ink wettability and total contact area. The adhesion fastness of the ink on the surface of 250 micron PET film was improved by the action of organic chemistry and physics.

With the development of bag-making and Printing Technology, 250 micron pet film has entered the color revolution era, which has promoted the development of flexible plastic packaging products to a deeper and higher level.